Gianfranco Novellini

Dedicated to your well-being for 50 years

Gianfranco Novellini began the business in Mantua in January 1966. In that year, he filed a request with the local Chamber of Commerce to open an artisan ironworking activity in Terziario Alley within the historic centre of Mantua. While working with screen and window materials in 1976, he came up with the idea that made Novellini what it is today: the construction of shower enclosures.

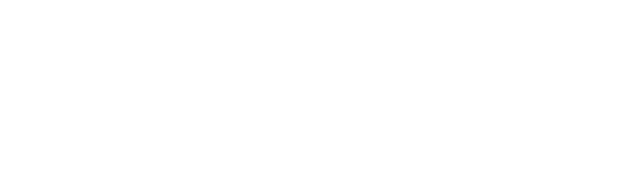

50 years later, the Novellini group is the European leader in the production of shower enclosures, shower cubicles and jacuzzis, with factories in both Italy and France, branches in key European countries and representatives on different continents. We have 27 branches worldwide, eight production sites and one million shower cubicles manufactured every year. We have been taking care of your well-being for 50 years!

Our values have always been to

Putting people at the heart of our decisions, make quality of life a priority and always let passion drive our work. These factors have led us to adopt an effective and sustainable production philosophy which guarantees your well-being.

from raw materials to the finished product

paying high attention to the quality of the product

client satisfaction

respect for the safety of our environment